- Home

- Applications

- Hydraulic System for CNC Lathe

Hydraulic System for CNC Lathe

Challenges of Traditional Hydraulic Systems in CNC Lathes

Main Applications of Hydraulic System: Workholding (Chuck and Tailstock)、Turret Tool Change、Spindle Braking

Challenges:

- Hydraulic Pump Idling for Long Periods:

In CNC lathes, chucks and tailstocks do not require continuous hydraulic supply during machining. However, traditional hydraulic systems keep the pump running continuously, leading to unnecessary energy consumption. - Low Pressure Demand but High Sensitivity to Pressure Fluctuations:

During workholding and turret tool changing, a high-pressure surge is required instantly. Traditional hydraulic units struggle to respond quickly, causing pressure drops that negatively impact machining accuracy. - Overheating Issues:

Continuous operation of traditional hydraulic systems generates excessive heat, degrading the performance and stability of hydraulic oil, which affects machining precision.

Benefits of Switching to ANYPOWER Servo Hydraulic System:

- Pressure is supplied only when needed, eliminating unnecessary energy consumption during pressure holding.

- Fast response time (0.01s), minimizing pressure drops and improving machining accuracy.

- Prevents overheating from continuous operation, reducing the impact of high temperatures on machining precision and hydraulic oil stability.

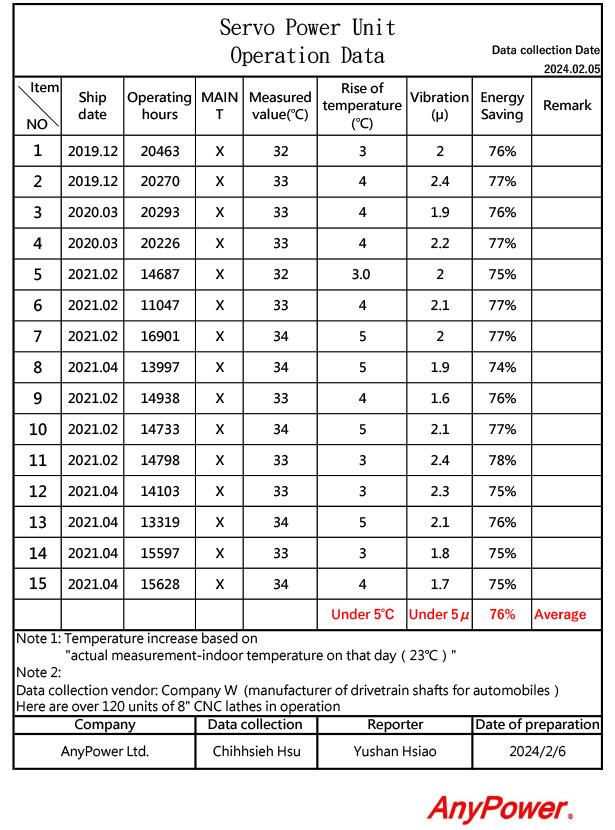

Application Cases

Background

- Automobile Transmission Shaft Processing Factory

- There are more than 120 CNC lathes in the factory.

- From 2019 to 2021, 15 Anypower servo hydraulic units have been replaced one after another.

Point

- All 15 units have been running for over 10,000 hours each.

- There are no maintenance records to date.

※ Although the initial purchase cost is higher than traditional options, the electricity bill has already been recouped.

※ Zero maintenance means zero service costs, saving company expenses.

These are actual measurement data from Company W. There are 15 servo hydraulic units

Testing Period:

From 1 pm March 1, 2018

To 11am Sep 6, 2018

Total operated 4088 hours

Total power consumption: 665.8 kwh (0.163 kwh per hour)

24 hours operation test (Mon to Sat)

Produce 1 component in 52 seconds.

Average producing 48 component in one hour

takes Servo hydraulic unit 0.16 kwh

and takes piston type hydraulic unit 0.68 kwh.

Conclusion: Servo hydraulic unit saves 76% energy than piston type hydraulic unit

Testing Period:

From 1 pm March 1, 2018

To 11am Sep 6, 2018

Total operated 4088 hours

Total power consumption: 665.8 kwh (0.163 kwh per hour)

24 hours operation test (Mon to Sat)

Produce 1 component in 52 seconds.

Average producing 48 component in one hour

takes Servo hydraulic unit 0.16 kwh

and takes piston type hydraulic unit 0.68 kwh.

Conclusion: Servo hydraulic unit saves 76% energy than piston type hydraulic unit

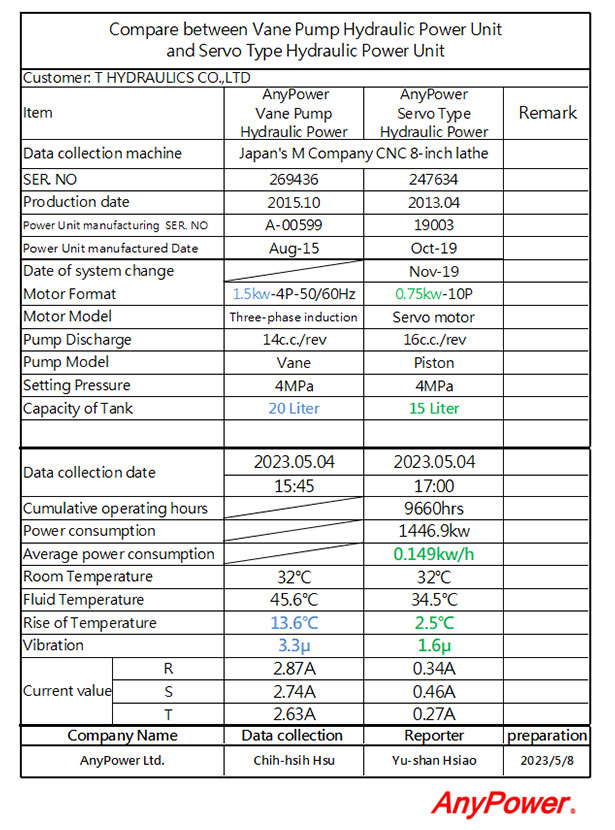

Background

- Company P purchased two machines from Japan's Company M.

- Both machines were originally equipped with traditional hydraulic units from Anypower. One of them was replaced with AnyPower servo hydraulic units.

Point

- The tank size was reduced from 20L to 15L.

- The motor was reduced from 2HP to 1HP.

- Improved temperature rise, noise levels, and vibration values were observed.

- Since the replacement with servo hydraulic units in 2019, there have been no maintenance records.

- Energy-saving efficiency reached 79%.

|

Item

|

AnyPower Servo Power Unit

AnyPower Servo Power Unit

|

Vane Pump Power Unit

|

| Power consumption per hour |

0.14kw-h

0.14kw-h

|

0.7kw-h |

|

Room Temperature |

29℃ | 28℃ |

|

Fluid Temperature |

30℃ | 39℃ |

| Rise of Temperature |

1℃

1℃

|

11℃ |

| Motor Temperature |

34℃ | 45℃ |

| Pump Temperature |

31℃ | 45℃ |

| Vibration |

1.3μ

1.3μ

|

3.5μ |

| SPL |

53db

53db

|

70db |

| Current value R |

0.43A | 2.92A |

| Current value S |

0.20A | 2.55A |

| Current value T |

0.32A |

2.90A |