- Home

- Applications

- Hydraulic System for Machining Center

Hydraulic System for Machining Center

Challenges of Traditional Hydraulic Systems in Machining Centers (MC)

Main Applications of Hydraulic Powerpack System:Tool Magazine Tool Change、Spindle Braking、Hydraulic Workholding (Hydraulic Fixtures)

Challenges:

- Instant High Flow Demand:

During tool changes and workholding, a high hydraulic flow is required instantly. However, traditional hydraulic units respond slowly, reducing machining efficiency. - Hydraulic Stability Affects Machining Accuracy:

A significant pressure drop can weaken workholding force, leading to reduced machining accuracy and poor surface quality. - Large Space Occupation:

Traditional hydraulic systems require additional cooling units to prevent overheating, and the oil tank is large, affecting the overall machine layout.A larger oil tank increases hydraulic oil consumption during each oil change, leading to higher maintenance costs.

Benefits of Switching to ANYPOWER Servo Hydraulic System:

- Ultra-fast response (0.01s

- Minimized pressure drop, resulting in enhanced machining accuracy and surface quality.

- No additional cooling system required, eliminating the cost and energy consumption of an oil cooler. Compact oil tank design, reducing machine footprint, CO₂ emissions, and hydraulic oil consumption during oil changes.

Application Cases

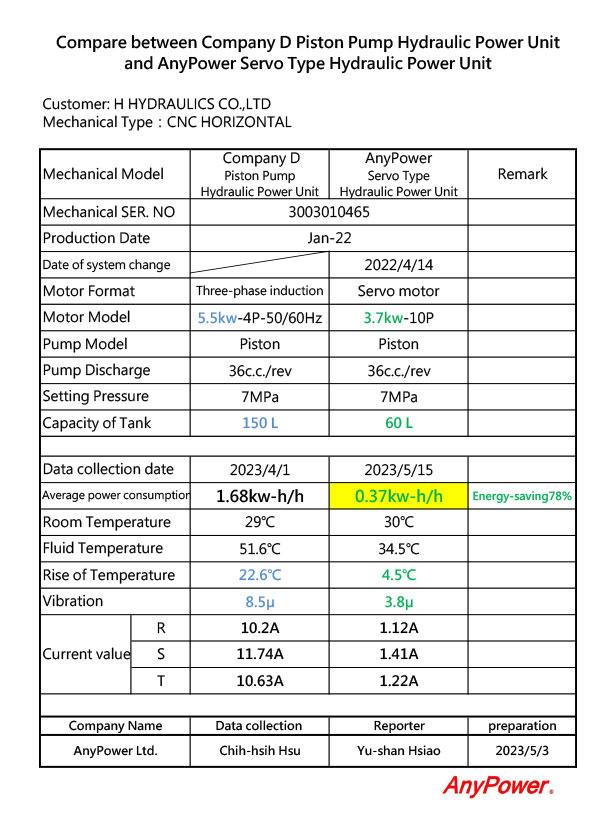

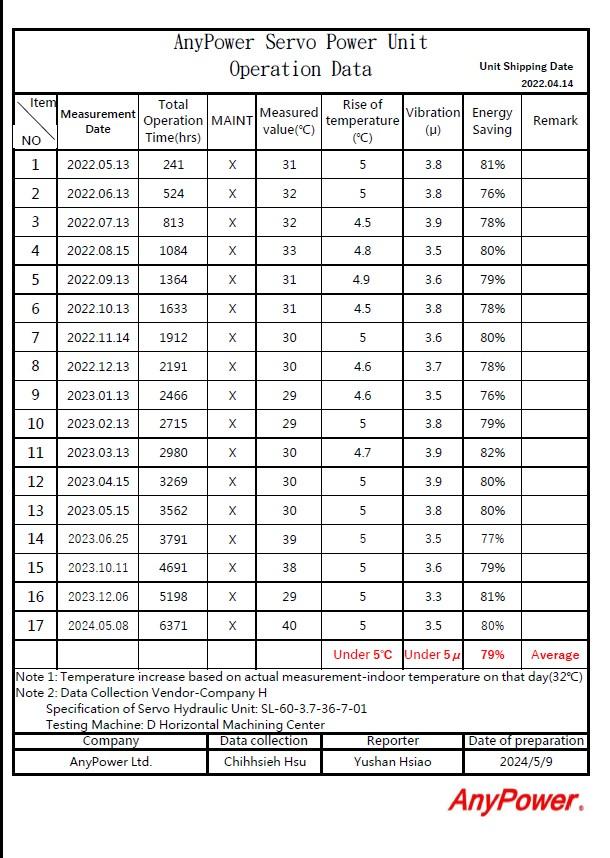

Background

- Test Machine: Horizontal Machining Center.

- The machine underwent maintenance and had Anypower servo hydraulic units installed.

Point

- The size of the oil tank for the old hydraulic equipment was reduced from 151L to 60L.

- The motor for the old hydraulic equipment was reduced from 7.5HP to 5HP.

- Temperature rise, vibration values, and current values all decreased according to actual measurements.

- The vibration value for the old hydraulic equipment decreased from 8.5u to 3.8u.

- There have been no maintenance records to date.

※ The reduced oil tank size leads to lighter weight and indirectly lowers carbon emissions.

※ Zero maintenance means zero service costs, saving company expenses.

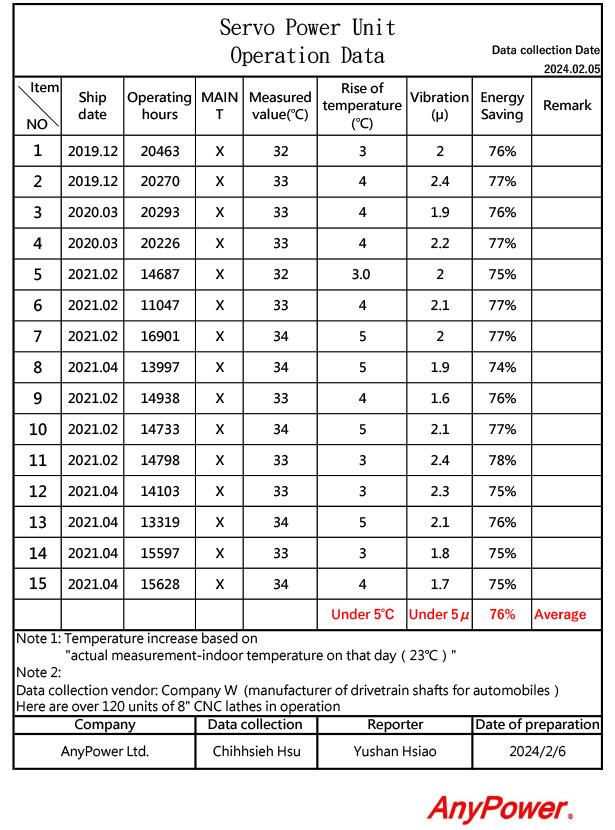

Background

- Air compressor manufacturing plant

- First time adopting an energy-saving hydraulic unit.

Point

- The tank size was reduced from 20L to 15L.

- The motor was reduced from 2HP to 1HP.

- Improved temperature rise, noise levels, and vibration values were observed.

- Since its delivery in 2019, it has operated for over 25,000 hours.

- Energy-saving efficiency reached 80%.

※ Although the initial purchase cost is higher than traditional options, the electricity bill has already been recouped.

※ Zero maintenance means zero service costs, saving company expenses.

Testing Period:

From 1 pm March 1, 2018

To 11am Sep 6, 2018

Total operated 4088 hours

Total power consumption: 665.8 kwh (0.163 kwh per hour)

24 hours operation test (Mon to Sat)

Produce 1 component in 52 seconds.

Average producing 48 component in one hour

takes Servo hydraulic unit 0.16 kwh

and takes piston type hydraulic unit 0.68 kwh.

Conclusion: Servo hydraulic unit saves 76% energy than piston type hydraulic unit

|

Item

|

AnyPower Servo Power Unit

AnyPower Servo Power Unit

|

AnyPower Piston Pump Power Unit

|

| Power consumption per hour |

0.13kw-h

0.13kw-h

|

0.68kw-h |

|

Room Temperature |

29℃ | 29℃ |

|

Fluid Temperature |

31℃ | 37℃ |

| Rise of Temperature |

2℃ 2℃

|

8℃ |

| Motor Temperature |

33℃ | 43.5℃ |

| Pump Temperature |

31℃ | 43.5℃ |

| Vibration |

1.1μ

1.1μ

|

3μ |

| SPL |

55db

55db

|

69db |

| Current value R |

0.41A | 2.82A |

| Current value S |

0.22A | 2.51A |

| Current value T |

0.30A |

2.88A |

Servo hydraulic unit saves

80

%

energy than Piston type hydraulic unit

Background

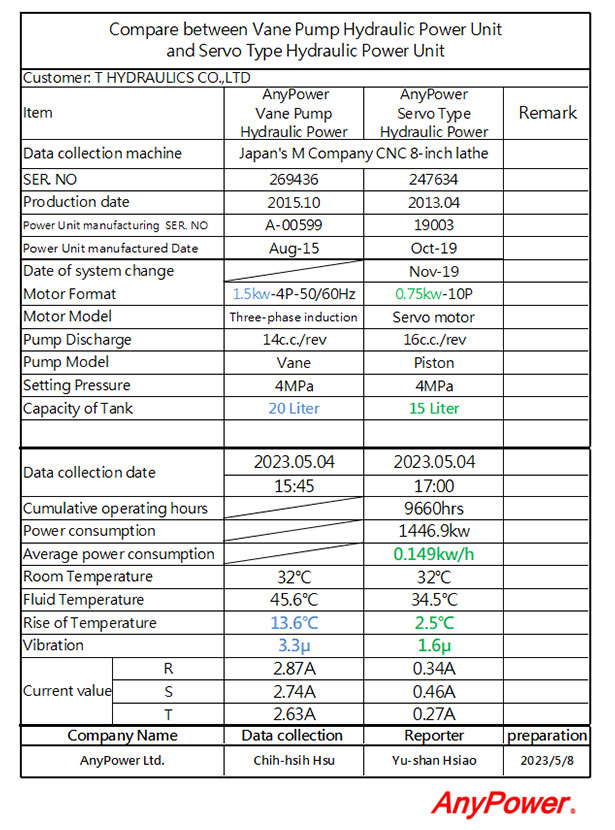

- Company P purchased two machines from Japan's Company M.

- Both machines were originally equipped with traditional hydraulic units from Anypower. One of them was replaced with AnyPower servo hydraulic units.

Point

- The tank size was reduced from 20L to 15L.

- The motor was reduced from 2HP to 1HP.

- Improved temperature rise, noise levels, and vibration values were observed.

- Since the replacement with servo hydraulic units in 2019, there have been no maintenance records.

- Energy-saving efficiency reached 79%.

|

Item

|

AnyPower Servo Power Unit

AnyPower Servo Power Unit

|

Vane Pump Power Unit

|

| Power consumption per hour |

0.14kw-h

0.14kw-h

|

0.7kw-h |

|

Room Temperature |

29℃ | 28℃ |

|

Fluid Temperature |

30℃ | 39℃ |

| Rise of Temperature |

1℃

1℃

|

11℃ |

| Motor Temperature |

34℃ | 45℃ |

| Pump Temperature |

31℃ | 45℃ |

| Vibration |

1.3μ

1.3μ

|

3.5μ |

| SPL |

53db

53db

|

70db |

| Current value R |

0.43A | 2.92A |

| Current value S |

0.20A | 2.55A |

| Current value T |

0.32A |

2.90A |